It is based on laying materials evenly on the belt. The belt is made of 12-60 mesh stainless steel wire, pulled by driven device, comes and goes in drying machine. Hot air come through materials, and steam discharge from weep holes. So that materials are dried.

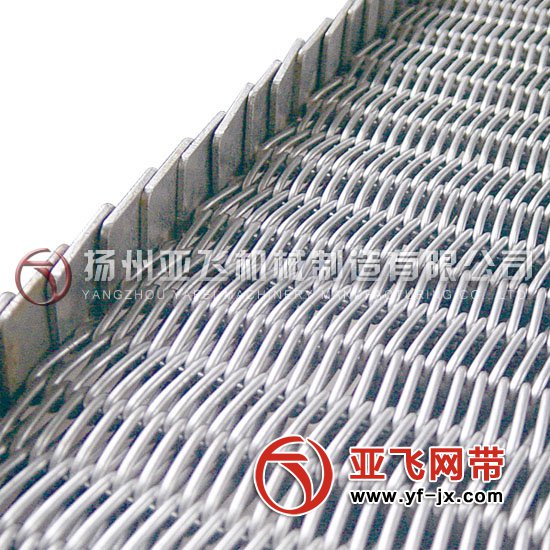

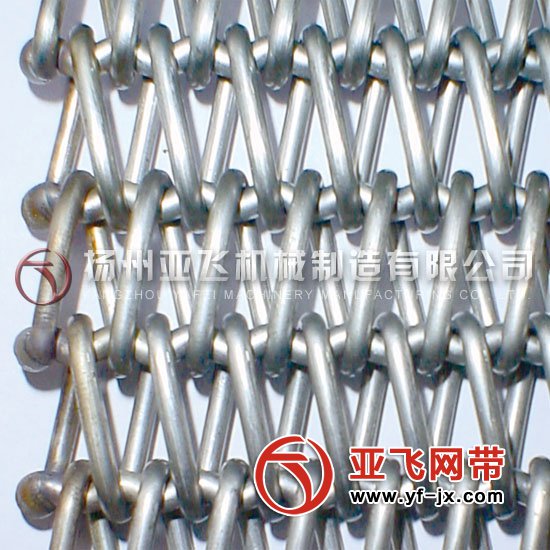

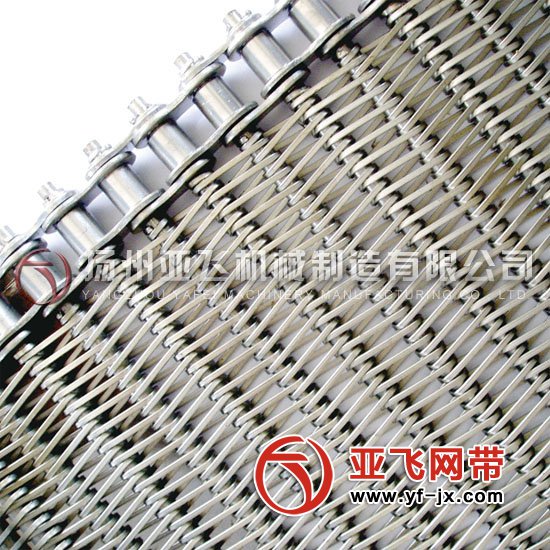

Catalyst drying wire mesh belt: It is made of high strength stainless steel wire, such as SUS304, SUS316L, etc. It is rustproof, acidproof and alkali-resistant, high temperature resistant, and high temperature resistant. The mesh holes is even. It has good tensile strength. The main types are balanced type, compound balanced type, flat wire type, etc. The edge is neatly welded. It is driven by rooler, without deviation. It is widely used in chemical catalyst roasting belt kiln. The catalyst can be placed onto a stainless steel tray, and then be conveyed to a kiln for roasting.